Diesel fuel injection systems—Lucas Diesel Systems

1 Compression ignition combustion processes

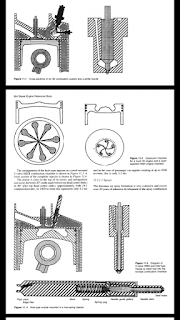

Introduction of fuel In indirect injection engines, the fuel is introduced via pintle nozzles into an anti-chamber to the space above the piston, which is called a 'prechamber' or a 'swirl chamber', depending upon the intensity of rotary air motion in this chamber. A swirl chamber layout is shown below in Figure 11.1 together with a much magnified section through a pintle nozzle. In IDI engines, much of the energy to mix the fuel with the air comes from the air motion, including swirl before ignition and combustion- driven mixing in the swirl-chamber throat and above the piston after ignition.

When fuel pressure is applied to the differential area between the guide and the seat, the needle lifts when the force developed exceeds the preload in the spring that holds the needle valve closed. If the pressure is applied progressively, an 'obturator' in the nozzle hole restricts flow during the first part of the valve. This controls the initial rate of injection to reduce noise. At the bottom of the needle is a 'pintle' which forms the spray into a hollow cone Indirect injection (IDI) engines are being replaced progressively by direct injection (DI) engines, from the larger sizes downwards, and all European truck and larger engines have been direct injection diesel engines for some time. In most of these combustion systems, more of the energy to mix the fuel with the air comes from the momentum imparted to the fuel as it leaves the nozzle. In small high speed direct injection engines for van and passenger car applications, the combustion chamber has a high swirl re-entrant bowl (also known as having a 'squish lip') to promote turbulence and hence faster mixing towards the end of combustion. In the intermediate medium truck (1 litre/cylinder) size, both quiescent and swirl-assisted combustion have their champions. The quiescent chamber requires more nozzle holes as shown in Figure 11.2.

The arrangement of the hole-type injector in a swirl-assisted 2-valve HSDI combustion chamber is shown in Figure 11.3. A cross section of the complete injector is shown in Figure 11.4. The piston is close to the top of its travel, and autoignition can occur, between 20° crank angle before top dead centre (btdc) to 40° after top dead centre (atdc), approximately, with 18:1 compression ratio. At 2400 rev/min this represents only 4.2 ms and in the case of passenger car engines rotating at up to 4500 rev/min, this is only 2.2 ms.

Sprays

The literature on spray formation is very extensive and covers over 20 years of intensive developmen of the spray combustion processes. During this period the fuel injection equipment has changed considerably. Early papers reflect the performance of injection systems which provided pressures across the nozzle holes that rarely exceeded 500 bars. Some of the injected fuel may be spread along the wall by its own momentum and that of the air swirl. The careful observations by many academic and industrial researchers provided empirical relationships and insight into the break-up of liquid sprays into ligaments, droplets and daughter droplets. Several alternative models of the various combustion processes were developed.

If the injector nozzle holes are reduced in diameter, and the fuel pressure across them is increased to obtain the same penetration in the compressed air charge, several workers found that the soot and paniculate matter in the exhaust were reduced

. In North America, high injection pressures have been common for many years in injection systems for truck engines which have been equipped with shallow quiescent combustion chambers. More recent work to apply mixing models to guide further reduction in soot generation has shown that these chambers respond well to further improvements in atomization.

. In addition, the large surface area of the fuel droplets expedites mixing and evaporation. In the 199Os injection pressures in European fuel injection systems rose to over 1000 bars at the nozzle and the upward trend continues through 2000 bars in the late 1990s to reduce the mass of particulate matter in the exhaust.

A typical diesel injection spray leaves each nozzle hole with a narrow included angle, and develops a head vortex where spray momentum is transferred to the compressed air. Each successive element of fuel seems to pass through the head vortex of the previous element, to form a new head vortex further across the bowl until the combustion chamber wall is reached, or the injection is terminated. The spray entrains air as it moves through the air in the combustion chamber6. The air entrainment and mixing models, some of which have been extensively validated against experimental results, show that when fuel is introduced into the combustion chamber as finely atomized sprays, the air entrainment increases providing a mixture which is closer to stoichiometric near the centre of each spray. The generation of diesel sprays by the injector nozzle has been studied with large-scale models. Above a critical pressure ratio, cavitation in the nozzle hole occurs which finely divides the fuel before it leaves the hole. In consequence the spray angle is larger and more air is entrained into the spray.

U Ingnition

Compression ignition combustion occurs only after a delay of approximately 0.0002 to 0.002 seconds after the start of injection.

This delay occurs because:

• The fuel has to travel into the combustion chamber.

• It has to mix with the air sufficiently to form a near-stoichiometric mixture.

• The fuel has to evaporate by taking heat from the compressed air.

• The mixture has to heat up to the auto-ignition temperature (Figure 11.5).

• Certain chemical reactions must take place in which unstable hydrocarbon-oxygenate species form which will ignite spontaneously.

Pre-mixed burn

Fuel which has been injected into the combustion chamber leaves the nozzle at 150 to 500 m/s, so the 20 to 30 mm radius of an HSDI combustion chamber can be traversed by a liquid jet in 0.04 to 0.2 ms, and somewhat longer by the evaporating droplets in a finely atomized spray tip. A significant proportion of the fuel injected during the ignition delay period will have mixed with the air in the combustion chamber when the first element ignites spontaneously (autoignition). Thus virtually all of the fuel which is injected in the ignition delay period (less between one and two crank degrees depending upon the injection pressure and the engine speed) is consumed in the premixed burn, unless the injection is specifically configured to avoid this (for example the M-combustion system16.

The premixed burn provides the rapid initial heat release which is typical of unrefined direct injection combustion systems, and causes a rapid increase in cylinder pressure that is the origin of combustion noise and in extreme cases piston failures. Fuel injection system developments such as pilot injection (pilot) and initial rate controls (IRC) have evolved to control the initial rate of heat release .

Diffusion burn

Fuel that is injected after ignition meets very different temperature and pressure conditions to that injected before ignition. The conditions may exceed the critical temperature and pressure so that the fuel flashes into vapour as it gains heat. The temperature in the combustion chamber is sufficient to pyrolize fuel if insufficient oxygen is available to burn it, especially near the centre-line of a spray. The rate of consumption of the fuel governed mainly by the rate at which it is mixed with sufficient oxygen and the exhaut emissions reflect this dependence. When the piston moves down from top dead centre, the vortices generated by the movement of gas force the burning mixture over the lip of the combustion chamber (reverse squish). If the lip is provided with a sharp edge, the turbulence caused will promote even more intimate mixing between fuel and air and will reduce much of the soot formed previously. This is very beneficial for high speed direct injection engines; but calculation of the remaining soot is not easy.

Formation of nitric oxide by lean combustion

Nitrogen and oxygen will combine together to form nitric oxide when heated to temperatures above 1500 K, primarily by the Zeldovich mechanism, although several other chemical reactions have been mentioned in the literature. Under steady state conditions, the rate of formation of nitric oxide increase rapidly with temperature as shown in Figure 11.6. The abscissa of Figure 11.6 is the equivalence ratio of the mixture which is unity when the mixture is stoichiometric. When the equivalence ratio is greater than 1, very little nitric oxide is formed, as the fuel consumes all the oxygen available at the flame front. As the mixture becomes leaner, increasing proportions of nitric oxide are formed in the mixture. If the temperature is increased at an equivalence ratio of say 0.8, the initial step from 1500 K to 2000 K results in only 0.3% increase in nitric oxide formation as a result of a new equilibrium between O2, N2 and NO. The next 300 K leads to a similar 0.3% increase in nitric oxide formation. However, the increase of 300 K between the top two curves yields over 0.5% increase in the equilibrium value of nitric oxide.

Two courses of action are available to reduce nitric oxide formation:

(1) Reduction of the volume of lean mixture in the combustion process.

(2) Reduction of the peak local temperatures of lean burn combustion.

From these two basic options, a number of alternative treatments have emerged which are effective in reducing nitric oxide formation:

(1) Retarding the injection timing, to reduce the peak cycle temperature. (However the thermodynamic efficiency, and hence the fuel efficiency suffers.)

(2) Recirculating some exhaust gas in controlled proportions to dilute the oxygen available at part load conditions and slow the chemical reaction rate. If the recirculated exhaust gas is cooled, the temperature of combustion is reduced.

(3) Injecting water through the same spray nozzle as the fuel (the evaporation of the water reduces the peak cycle temperature).

(4) Reducing the oxide of nitrogen with catalytic combustion of extra fuel or ammonia injected into the exhaust system. The fuel injection system and electronic control unit are central to all these treatments; either directly, or indirectly since even the EGR and aftertreatments require a precise measurement of the fuelling to be effective without making other emissions worse.

Unburned hydrocarbons

A compression ignition engine emits far less unburned hydrocarbons at normal operating temperatures than intake- and port-injected spark ignition engines, simply because less fuel comes into contact with the film of lubricating oil in compression ignition engines. However, there are about six independent sources of unburned hydrocarbons in a diesel engine18. Of these, four are directly controlled by the fuel injection equipment:

(1) If fuel is injected at high velocity into the combustion chamber, before 20° crank btdc, the air motion mixes the fuel so effectively before ignition so that a mixture forms that becomes too lean to auto-ignite and too lean to sustain a flame. This is the 'lean-limit source' described by Greevesetal.

(2) Hydrocarbons trapped in the sac and holes downstream of the needle seat join the burning mixture late in the cycle, when air motion draws this fuel out19. Injector nozzles with smaller sacs or with valve-covers-orifice (VCO) confi- gurations reduce this volume as shown in Figure 11.7.

(3) Fuel that is injected late in the engine cycle, will find little oxygen in which to burn. As the piston descends, cylinder temperatures drop below the auto-ignition temperature.

(4) Fuel that is sprayed onto the combustion chamber walls, can conribute to unburned hydrocarbon emissions where the quantity of fuel on the wall exceeds the capacity of the air motion to evaporate it at some particular operating conditions or temperatures. Excess smoke may arise from such conditions also.

Origins of noise in diesel combustion processes

The rapid consumption of most of the fuel injected during the ignition delay period in the pre-mixed burn release heat very rapidly, and the cylinder pressure rises almost instantaneously. This imparts a large and steep-fronted force pulse to the sructure which excites most of the mechanical resonances and causes the surfaces of the engine to vibrate20. Acoustic radiation from the vibrating surfaces completes the transmission to the ear. The sound generated by traditional diesel combustion has a characteristic 'knock'; however the structure responds in the same way to mechanical impacts as the pistons move in their bores and in the timing drive. Subjectively the noise sounds very similar to combustion knock if it has a mechanical origin. Much of the literature suggests that combustion noise depends almost entirely upon the peak rate of pressure rise caused in turn by an initial peak in the rate of heat release. For individual engines, quite good relationships exist between peak rate of rise in cylinder pressure and the noise that originates directly in the combustion processes. However, when such relationships for several different engines are compared, large discrepancies appear

The shape of the cylinder pressure curve can be related to the Fourier Analysis (or spectrum) of the cylinder pressure quite simply:

(1) The compression ratio and turbocharger boost ratio directly influence the level of components up to 500 Hz (as well as indirectly influencing the peak rate of pressure rise via the compression temperature and hence the ignition delay).

(2) The peak cylinder pressure influences the average level of low frequency spectrum components up to between 500 and 900 Hz.

(3) The peak rate of pressure rise influences the components between 500/900 Hz and 3/5 kHz depending upon the engine speed, turbocharger boost (if any) and the rate of injection diagram.

(4) The second derivative of pressure with respect to time can influence very high frequency components (above 5 kHz). The first option to reduce combustion noise is to reduce the ignition delay and hence the quantity of fuel that contributes to the premixed burn. Increasing the compression ratio, heating the intake air, turbocharging or supercharging, fumigating and reducing heat transfer into the piston and cylinder head may be deployed to this end.

Pilot injection reduces the fuel injected during the ignition delay, and hence the heat released from the premixed burn.

Control of the initial rate of injection (IRC) and 'boot-shaped' injection rate diagrams are effective for the same reasons, but only if the control extend over most of the ignition delay; hence pilot is more appropriate for cool combustion conditions encountered in urban traffic and cold start/cold idle. Models of fuel injection systems which reduce combustion noise have been used to explore the design freedoms in such systems.

Exhaust gas recirculation will reduce the rate of the premixed burn and hence the peak rate of rise in the cylinder pressure. The modulation of the initial rate of fuel injection, either by pilot or IRC or combinations of these has become an area where the fuel injection equipment manufacturers can add value in terms of refinement in passenger car and public service vehicle applications.

Particulate emissions

Particulate emissions from compression ignition engines are mostly microscopic pieces of carbon, bound together with unburned hydrocarbons into particles which range in size from a few hundredths of a micron to over ten microns. Sulphate particles and particles formed from any metals in the fuel may add to the fine particulate emissions. The fuel injection equipment has a controlling influence upon the generation of soot-based particulates via the air entrainment in the sprays. If more oxygen can be introduced into the centre of the sprays by increasing atomization and spray velocity and hence air entrainment, less soot particles form in the centre of the sprays. This is the basis of soot and particulate reduction by reducing the nozzle hole diameter and increasing injection pressure. If the combustion system is designed to work with appreciable wall wetting, then the injection equipment is required to control the proportion of the fuel that is deposited upon the wall.

Soot reduction during subsequent combustion

As the piston of a HSDI engine descends, the burning mass of fuel and air is forced over the rim of the chamber, which generates considerable turbulence and mixes the remaining unburned hydrocarbons with the air above the piston crown. Incandescent particles of carbon are bought into contact with the remaining oxygen and up to 95% of them are burned completely. The detail of the complex motion involving swirl and squish giving rise to a moving toroid of air, into which the fuel is injected; followed by the expansion and spilling of this burning mass of air and fuel over a lip into the space above the piston as the piston starts to descend is difficult to model accurately. Further- more, as the soot in the exhaust is the difference between that generated during the earlier parts of the diffusion burn, and consumed in almost equal amounts by later diffusion burn processes, its computation involves the subtraction of two large quantities to predict a small difference. Research with a variety of mechanical fuel injection equipment devices indicates that the main injection must terminate as abruptly as is mechanically feasible, as well as meeting certain injection pressure criteria in order to minimize soot generation.

Traditional jerk pump

The traditional jerk pump was developed to give the prime example of a variable-delivery, positive displacement hydraulic

pump. Figure 11.8 shows the components of a traditional pump- pipe-nozzle system.

The chamber above the plunger within the barrel, in which high pressure is generated by upward movement of the plunger, is connected by a central drilling to a helical or angled groove cut into the side of the plunger. There are two drillings in the barrel wall, one to allow fuel to flow into the chamber when the plunger is withdrawn, which is known as the 'filling port' and a second drilling which is known as the 'spill port'. In operation, the plunger is withdrawn down the barrel, opening the filling port, allowing fuel to enter the chamber above the plunger from a low pressure supply. As the camshaft rotates and the cam bears upon the roller of the tappet, the plunger is driven upwards until it seals the filling port. The fuel trapped above it is pressurized rapidly, and the pressure opens the delivery valve. When the delivery valve opens, the rapid motion of the plunger creates a high pressure hydraulic wave in the injector pipe. The high pressure hydraulic wave travels along the pipe until it meets the seat of the needle valve in the injector. While the needle valve is closed, the wave is reflected, causing an additional pressure at the seat of the needle valve from the combined pressure of the incident and reflected waves. When the total hydraulic pressure on the differential area around the valve seat exceeds the nozzle opening pressure (NOP), the needle valve in the injector rises off its seat. The needle opens rapidly when the whole area of the needle is exposed to this pressure. Subsequent injection ensures that the valve remains open, held at its lift stop, despite any temporary fall in pressure caused by the needle displacement. Inside the injection pump, the plunger continues to travel upward until the helical groove in the plunger engages with the spill port. When this occurs, fuel flows through the central drilling to the helical groove and out through the spill port causing the fuel pressure in the chamber to collapse. This terminates the effective stroke of the pump and generates an expansion wave in the injector pipe. When this expansion wave reaches the drilling within the injector, it causes the pressure under the needle at the seat to collapse below the nozzle closing pressure. (NCP is the pressure which acts on the whole needle area to provide a force equal to that of the spring.) The spring above the needle then begins to accelerate the needle towards its seat with a force that is equal to the spring force minus the force due to any remaining pressure acting upon the bottom of the needle. The needle displacement is a modified sinusoidal movement as the spring relaxes and drives the needle onto its seat. As the expansion wave passes through the delivery valve, its spring begins to close the valve and the collar on the valve (Figure 11.9} enters the valve guide, thus separating fuel within the injection pump from fuel within the pumping chamber. As the delivery valve continues to close, the displacement of the collar multiplied by the area of the guide 'unloads' the system downstream to control the residual pressure within the pipe and hence reduces the risk of secondary injections (injections after the main injection which cannot burn completely as they appear near the end of the combustion process). Jerk pump operation is reliable and repeatable. The plunger and barrel are made to tight manufacturing tolerances with a very small clearance between them to contain the high injection pressures inside the pumping chamber. The rate of spill controls the collapse of line pressure and hence the rate of the expansion wave that terminates injection. This can be improved by machining the spill port to be oval or even spark eroding it to a parallelogram section to match the helix angle, in order to increase the rate of area increase as the port is opened.

These pumps are used on large truck engines with separate control of the timing of the start and end of injection. The cam rate, plunger diameter and nozzle characteristics are chosen to control soot generation by injecting at high pressures through small nozzle holes with an injection rate which increases as the injection timing is retarded.

شركة تنظيف موكيت بالاحساء

ردحذفشركة تنظيف شقق بتبوك

شركة تنظيف سجاد بتبوك

شركة تنظيف بيوت بتبوك