Caterpillar diesel engines

Types of engines pdf

Car engine types

Diesel engine

Definition and types of combustion engines with details Types of heat engine

Heat engine Internal combustion engines

Engine power types

Types of engine

What is engine

Car engine PDF

Engine car

Fuel cycle maintenance instructions:

- Use the recommended fuel

- Use of caterpillar fuel filters and water separators

- Keep the filter clean while changing it.

- Get rid of water and sediment in a tank Fuel.

- Keep the tank cover and filter clean Fuel

- Change the fuel filter at the recommended times.

The problems arising from not following the fuel cycle maintenance instructions and not using its original parts.

- Corrosion of spray holes due to the use of poor quality types The fuels contain foreign substances and also due to the use of filters Non-original fuel.

- Increasing the percentage of carbon in the fuel leads to the formation of deposits on Valves .

- Increase the percentage of non-combustible foreign bodies in the fuel Lead to deposits on the valves

- An increase in sulfur content in the fuel leads to valve pitting.

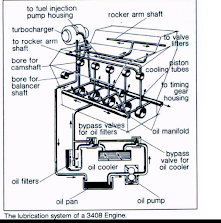

Lubrication cycle maintenance instructions

- Use the recommended CG4 oils

- Use caterpillar oil filters

- Maintain the cleanliness of the filter while changing it and make sure that it is not present Residual sealant

- Check the oil level

- Change the oil and filter at the recommended times

- Keep the oil filler cap clean while changing it

- Regularly taking and analyzing samples of oil (SOS)

What are the problems caused by not following the maintenance instructions of the lubrication cycle and using its original components?

- Collapses in the bearing seats due to too little oil or Use oils that violate the recommended specifications.

- Collapses in the piston due to lack of oil or use Oils contrary to the recommended specifications.

- Collapses in the turbo bearing seats due to lack of oil or use oils contrary to the recommended specifications.

- Corrosion of the bearing seats from the presence of dust particles or corroded metals as a result of not changing the oil filter in the recommended time or using non-filters are original.

- Collapses in the crankshaft due to too little or too little oil Violation of the recommended specifications.

- Corrosion in the crankshaft from dust particles or corroded metals as a result of not changing the oil filter in the recommended time, or using unused filters are original.

- Thermal discoloration in the turbine shaft due to lack of oil or Use oils that violate the recommended specifications.

- Fracture of the turbo shaft due to the collapse of the bearing seat due to a lack of quantity Oil or the use of oils contrary to the recommended specifications.

- Piston and shirt wear due to the presence of dirt particles or Corroded metals as a result of not changing the oil filter in the recommended time Using or using non-original filters.

- Corrosion in the turbine shaft due to the presence of dust or metal particles Corroded due to not changing the oil filter in the recommended time or Use non-original filters.

- Valve collapses due to lack of oil or use Oils contrary to the recommended specifications.

Air charge and exhaust cycle

Maintenance instructions for the air charge and exhaust cycle:

- Use of caterpillar air filters

- Monitor and clean the primary air filter

- Change the air filters.

- The weight of valve clearances

What are the problems that result from not following the maintenance instructions of the charge and exhaust cycle and from not using its original parts?

- Loud noise from the valves in the event of a large clearance.

- Strong black smoke due to insufficient air intake to block the air filter.

- The exhaust temperature is too high for the air filter to be clogged and leaked Inside the engine from another place or because the exhaust path is blocked

Engine cooling cycle

Engine cooling cycle maintenance

instructions

- Use caterpillar coolants in the recommended proportions of 50% water Pure + 50% anti-freeze + 3 to 6% anti-rust.

- Monitor coolant level.

- Cooling fan belt tension test.

- Add anti-rust at the recommended dates

- Add anti-freeze at the recommended dates

- Clean the cooling system when overheating occurs

What are the problems that result from not following the engine cooling cycle maintenance instructions and using the recommended fluids?

- Rust spread over the combustio

n chamber Primary, thermostat and water pump This is due to the absence of a rust inhibitor. - Carbon deposits on valves as a result of the engine being loaded at a temperature Below the minimum temperature Employment.

- The pistons stretch and stick to the shirts as a result of overheating.

- Cracks appear in the cylinder head as a result of overheating.

- The spread of rust on the surfaces of the shirts and the water pump due to the absence Rust inhibitor.

- The occurrence of cavitation and pitting by the bursting of steam bubbles on the surfaces the exterior of the shirts is due to the absence of antifreeze, which creates a layer On these surfaces to protect it.

- Damage to the water pump seal and deposits on the oil cooler resulted To clogging of the coolant ducts due to mixing an excessive amount of blocker Antifreeze.

volvo diesel engines

do diesel engines have spark plugs

ليست هناك تعليقات:

اضافة تعليق