TWO-DIMENSIONAL CASCADES

- What is turbine cascade?

- What is cascade effect in gas turbine engine?

- What are the three types of turbine blades?

- What is turbine and its function?

•

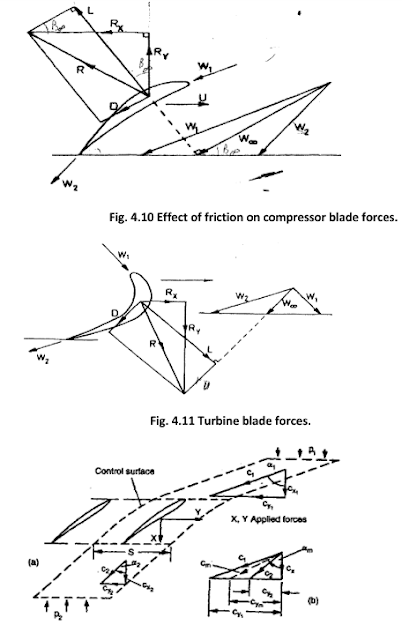

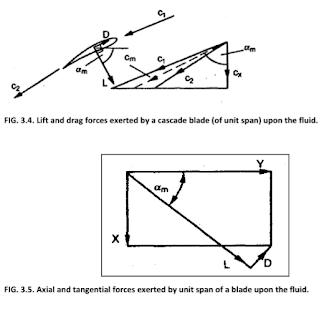

The operation of any

turbomachine is directly dependent upon changes in the working fluid’s angular

momentum as it crosses individual blade rows.

•

A deeper insight of

turbomachinery mechanics may be gained from consideration of the flow changes

and forces exerted within these individual blade rows.

•

The range of Mach number

in axial-flow turbomachines can be considered to extend from M = 0.2 to 2.5 (of

course, if we also include fans then the lower end of the range is very low).

Two main types of cascade

tunnel are:

(i) low-speed, operating in the range 20-60 m/s (ii) high-speed, for the compressible flow range of testing.

turbine cascade meaning

Conventional low-speed compressor

cascade wind tunnels

•

To obtain truly

two-dimensional flow would require a cascade of infinite extent. Of necessity

cascades must be limited in size, and careful design is needed to ensure that

at least the central regions (where flow measurements are made) operate with

approximately two-dimensional flow.

•

A suction slot is

situated on the ceiling of the tunnel just before the cascade to allow the

controlled removal of the tunnel boundary layer.

Carefully controlled suction

is usually provided on the tunnel sidewalls immediately upstream of the cascade

so that two-dimensional, constant axial velocity flow can be achieved.

•

For axial flow machines

of high hub—tip ratio (short blade), radial velocities are negligible and, to a

close approximation, the flow may be described as two-dimensional.

•

The flow in a cascade is

then a reasonable model of the flow in the machine.

•

With lower hub-tip

radius ratios (long blade), the blades of a turbomachine will normally have an

appreciable amount of twist along their length, the amount depending upon the

sort of “vortex design” chosen. However, data obtained from two-dimensional

cascades can still be of value to a designer requiring the performance at

discrete blade sections of such blade rows.

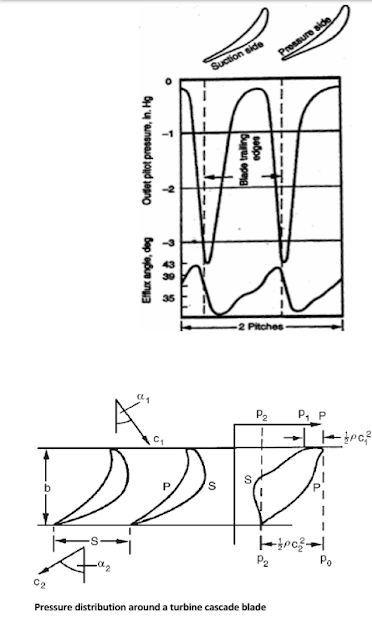

Pressure distribution around a turbine cascade blade

Turbine cascade performance

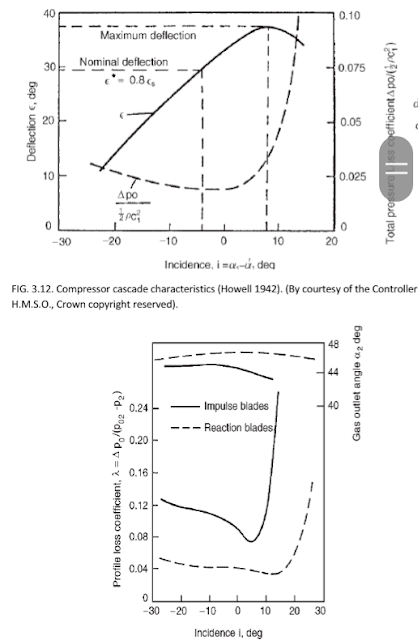

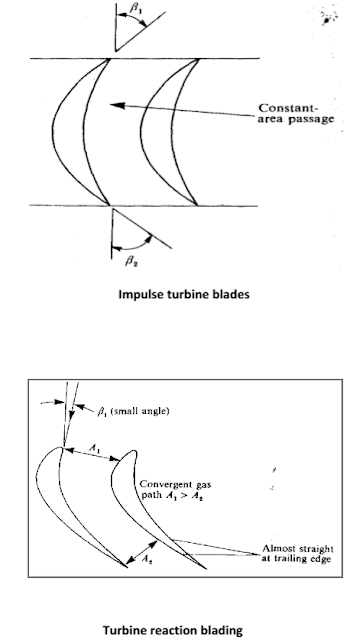

Figure 3.14 shows results

obtained by Ainley (1948) from two sets of turbine cascade blades, impulse and

“reaction”. The term “reaction” is used here to denote, in a qualitative sense,

that the fluid accelerates through the blade row and thus experiences a pressure

drop during its passage. There is no pressure change across an impulse

blade row. The performance is expressed in the form ʎ= Δpo/(po2 -p2) and ∝^2 against incidence.

From these results it is observed

that:

(a) the reaction blades have a much wider range of low loss

performance than the impulse blades, a result to be expected as the blade

boundary layers are subjected to a favorable pressure gradient,

(b) the fluid outlet angle 2

remains relatively constant over the whole range of incidence in contrast with

the compressor cascade results.

Two important geometric

variables, which define blade shape are

•

Blade thickness

distribution, t/l, and

•

Blade camber line shape

distributions y/l, which may be circular or parabolic arce form or any other

form. It determines the blade camber angle, θ.

• Blade camber and thickness distributions are generally presented as tables of y/l and t/l against x / l.

Beside the blade profile (thickness&camber distributions) there are two important geometric variables, which define the cascade are

•

the space-chord ratio,

s/l, and

•

the stagger angle,Ƹ,

The stagger angle,ξ,

is the angle between the chord line and the

reference direction (which is the tangent to or the line perpendicular to the

cascade front).

The importance of the stagger

angle, x,

It affects the following:

1- the blade angles

2- the relative amount of diffusion or

acceleration

3- the energy transfer in case of rotor

cascade (to/from the blade from/to the fluid i.e. turbine or compressor)

4- losses or drage coefficient.

Effect of stagger angle on

cascade performance.

A,B & C — compressor

cascades.

D,E & F — turbine cascades.

Turbine

reaction blading

There is a pronounced increase in

total pressure loss as the incidence rises beyond a certain value and the

cascade is stalled in this region. The precise incidence at which

stalling occurs is difficult to define and a stall point is arbitrarily

specified as the incidence at which the total pressure loss is twice the

minimum loss in total pressure. Physically, stall is characterised (at positive

incidence) by the flow separating from the suction side of the blade surfaces.

With decreasing incidence, total pressure losses again rise and a “negative

incidence” stall point can also be defined as above. The working range is

conventionally defined as the incidence range between these two limits at which

the losses are twice the minimum loss. Accurate knowledge of the extent of the

working range, obtained from two-dimensional cascade tests, is of great

importance when attempting to assess the suitability of blading for changing

conditions of operation.

A reference incidence angle

can be most conveniently defined either at the midpoint of the working range

or, less precisely, at the minimum loss condition. These two conditions do not

necessarily give the same reference incidence.

5.7 HIGH-SPEED FLOWS

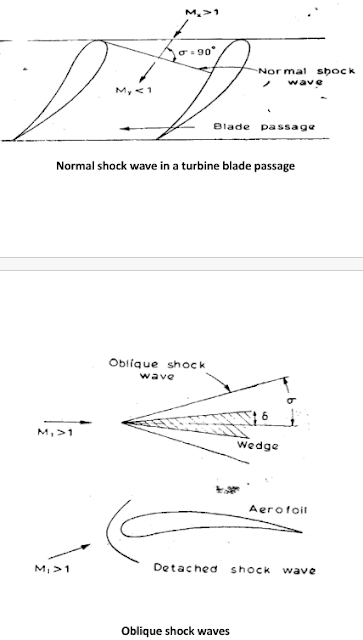

Many turbines and compressors

experience flows at high Mach numbers. The high Mach number flow gives rise to

some special problems which are characteristic of only high speed flows. Most

of these problems arise due to the acceleration or deceleration (to subsonic

Mach numbers) of supersonic flows in blade passages; expansion and compression

waves are generated which affect the nature of flow and losses in these

machines.

As stated before, when the Mach

number reaches unity, the flow chokes and the maximum mass flow rate is

governed by Eq. (5.82).

It is well known that in practice

a supersonic flow decelerates to subsonic through a shock wave. This may be

either normal or inclined to the direction of flow. In actual practice both the

types of waves exist in supersonic machines.

The shock wave is an

irreversibility and leads to stagnation pressure loss and increase in entropy.

HIGH-SPEED FLOWS

•

Many turbines and

compressors experience flows at high Mach numbers.

•

The high Mach number flow

gives rise to some special problems which are characteristic of only high speed

flows.

•

Most of these problems

arise due to the acceleration or deceleration (to subsonic Mach numbers) of

supersonic flows in blade passages; expansion and compression waves are

generated which affect the nature of flow and losses in these machines.

•

When the Mach number reaches

unity, the flow chokes (there is a maximum mass flow rate which is indepentent

the decrease of the downstream pressure).

HIGH-SPEED FLOWS (Continue)

•

It is well known that in

practice a supersonic flow may decelerate to subsonic through a shock wave.

•

This may be either

normal or inclined (oblique shocks) to the direction of flow. In actual

practice both the types of waves exist in supersonic machines.

•

The shock wave is an

irreversibility and leads to stagnation pressure loss and increase in entropy.

Normal

shock wave in a turbine blade passage

ليست هناك تعليقات:

اضافة تعليق