GAS TURBINES

MAIN THEMES

● Introduction

● Main types of gas turbines

● Basic parameters of gas turbines

● Stage of gas turbine

● Stator of gas turbine

● Rotor of gas turbine

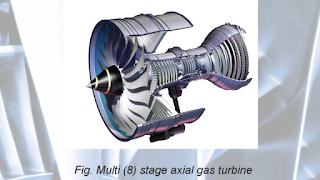

● Multistage gas turbine

● Stator cooling

● Conclusions

INTRODUCTION

● In turbines is converted heat and pressure energy to kinetic energy and mechanical work with very high efficiency

● The conversion is provided in stator and rotor canals

● In stator vanes is converted heat and pressure energy to kinetic energy

● In rotor blades is converted heat and pressure energy to kinetic energy and mechanical work

● Obtained performance on turbines is exploited for compressor and assembly drive. In case of turboshaft engines, performance is also used for propeller or rotor drive.

● Ground power unit use converted energy for drive of electric generators or compressors and many types of equipments.

REQUIREMENTS

● High performance

● High reliability

● High lifetime

● High efficiency

● Minimal weight and dimensions

● Simple construction and maintenance

● Low price

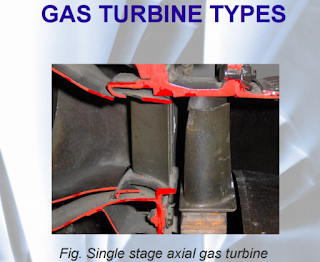

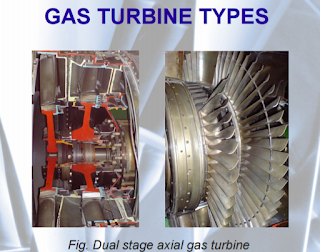

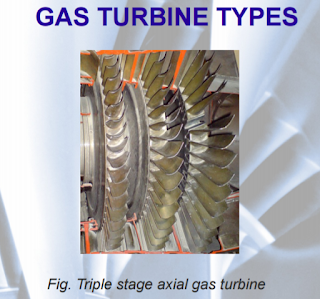

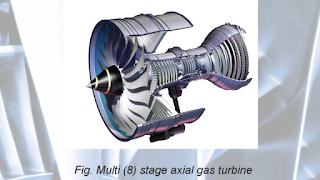

GAS TURBINE TYPES

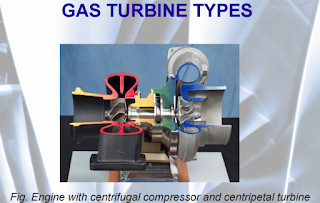

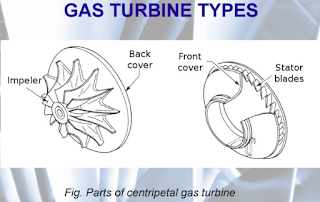

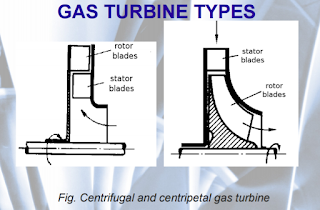

TYPES BY DIRECTION OF FLOW

● Radial

● Centrifugal

● Centripetal

● Axial

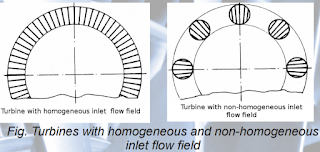

TYPES BY INLET FLOW FIELD

● Turbines with homogeneous inlet flow field

● Turbines with non-homogeneous inlet flow field

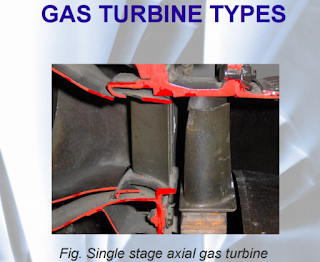

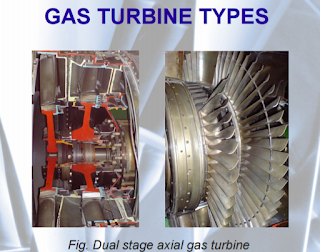

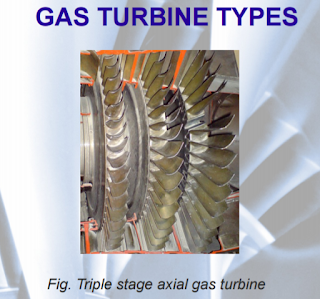

TYPES BY NUMER OF STAGES

● Single stage

● Dual stage

● Triple stage

● Multi stage

TYPES BY NUMBER OF SPOOLS

● Single spool turbines

● Dual spool turbines

● Triple spool turbines

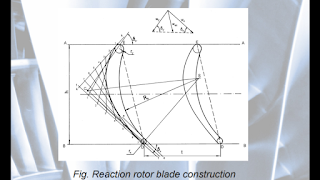

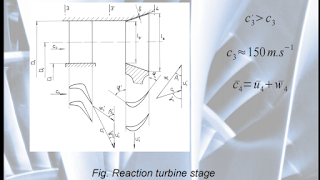

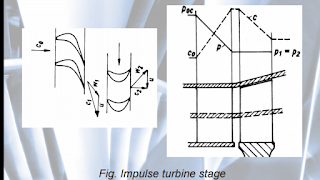

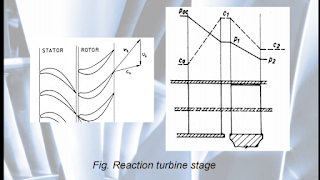

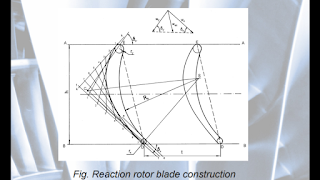

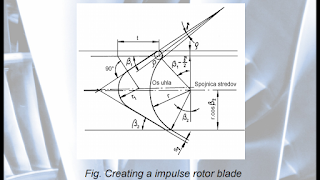

TYPES BY REACTION OF STAGE

● Impulse stage

● Impulse/Reaction (Reaction) stage

Flow rate

● Depends on construciton 0,5-300kg.s-1

Thermal gradient

● Max. 30kJ.kg-1on one stage

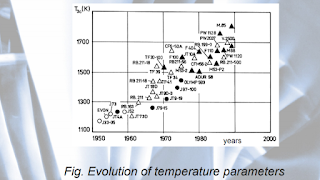

Temperature before turbine

● Non-cooled turbines max. 1000°C

● Cooled turbines 1200°C and more.

RPM (Revolutions per minute)

● Depends on construction 5-90.103 min-1

Reliability

● Means reliability of blades. At present days in modern engines its approximately 10000 hours.

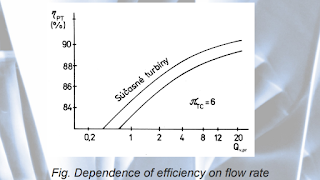

Efficiency

● Single stage turbines 0,82-0,90

● Multi stage turbines 0,88-0,94

Cooling air

● Depend on intensity of cooling (approximately 5% from flow

rate)

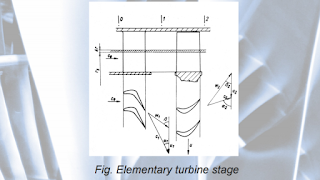

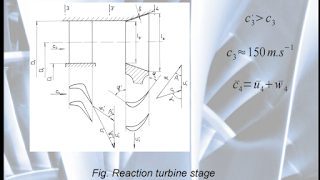

TURBINE STAGE

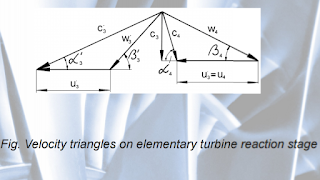

Forces on rotor blade are created by:

● Aerodynamic forces created by fluid around

blades (impulse action of gases)

● Reaction action of gases in convergent rotor

blades canal where are gases accelerated

● Work transferred to blades of elementary stage from 1kg of gas From Euler equation:

● Efficiency of multistage turbines is higher than efficiency of every single stage (in compressor that's NOT true)

● Efficiency of multistage turbines is 0.88-094

● Efficiency increasing by number of turbine

stages.

● Efficiency of multistage turbines is higher than efficiency of every single stage (in compressor that's NOT true)

● Efficiency of multistage turbines is 0.88-094

● Efficiency increasing by number of turbine stages

● Lower velocity of gases as in single stage

● Losses from stage before are exploited in the next one

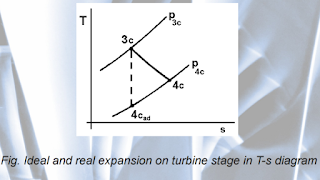

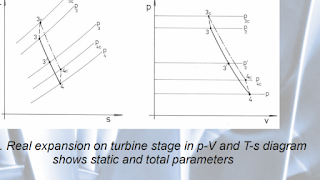

Reaction of elementary stage

● Is ratio of adiabatic static work of rotor and

adiabatic static work of elementary stage.

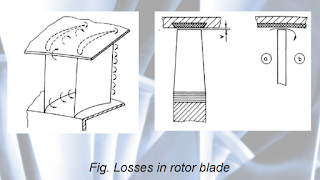

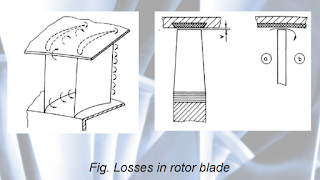

Profile losses

● in stator and rotor as well

● These losses are generated as soon as gas

fluid around vanes/blades.

● Friction losses (boundary layer)

● Shock phenomenas

● Wakes (high angle of atack)

● Profile losses are higher in rotor.

Secondary losses

● Generated by pair-wakes (induced drag)

● Losses in redial spaces between rotor blade

and turbine caseOther losses.

● Losses in bearings

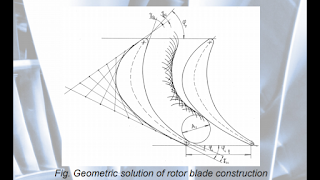

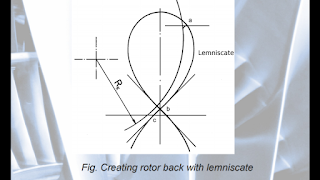

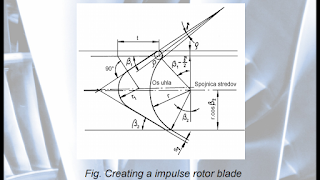

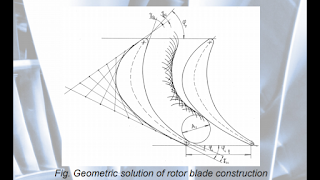

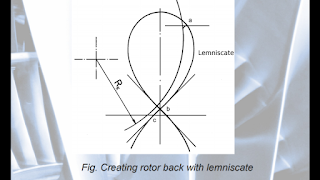

BLADE GEOMETRY

● Characteristic shape of rotor blade is the longitudinal shape

● In elementary stage is determined in the middle diameter ( by flow equation )

● The real flow is spatial. The peripheral speed is increase from rotor root to rotor tip. Absolute velocity and pressure changed as well. All of these parameters are connected

● The real flow is – spatial, compressible, viscous and non-stationary

● GEOMETRY of blade must accepted these facts.

MULTISTAGE GAS TURBINE

● Created by compiling of turbine stages in a row

● Modern engines used 6 and more stage

turbines because:

● There are high thermal gradients

● Higher efficiency

● Better collaboration with compressor ( bigger diameter – lower RPM )

● Smooth shape of engine

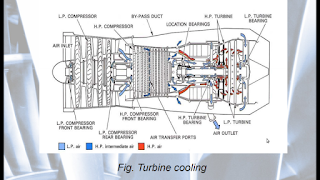

GAS TURBINE COOLING

Sources of cooling

● Air from fan

● Air from low pressure compressor

● Air from secondary flow on CC

● Air from secondary flow ( turbofan engines )

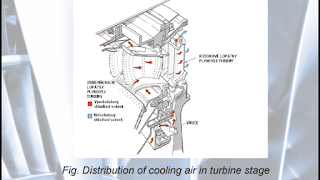

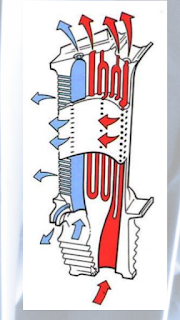

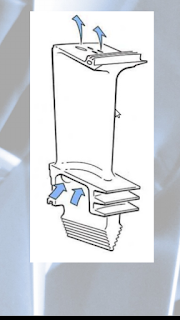

BLADES COOLING

Methods of blade cooling

● Convective ( Internal cooling )

● Film cooling

● Transpiration cooling

Film cooling

● Cooling is provided with cooling air, which is delivered through the holes on the blade surface.

● Cooling with air film is more efficient as convective cooling.

● Transpiration cooling

● Transpiration cooling is similar technique of

cooling as cooling with air film.

● In this case is generated a homogeneous

surface of cooling air on surface of blade

● Transpirationally cooled blades have no holes.

Air flow through the porous surface of blade.

gas turbine

gas turbine engine

gas turbine ge

gas turbine generator

gas turbine siemens

gas turbine locomotive

gas turbine cycle

gas turbine combustor

gas turbine combustion

gas turbine 7fa

gas turbine parts

gas turbine jobs

gas turbine engine for sale

gas turbine for sale

gas turbine manufacturers

gas turbine components

gas turbine applications

gas turbine world

gas turbine technician salary

ليست هناك تعليقات:

اضافة تعليق